Fast Processing

Processing time per batch is only 7 to 17 minutes.

Extensive Experience

Over 10 years of non-autoclave laminating machine

OUR ADVANTAGE

Flexible Production

Capable of handling both bulk and single glass pieces.

Safe and Efficient

Advanced technology ensures safer and more efficient operation.

Fully Automated Operation

Highly automated design for simple and efficient use.

Multi-Film Compatibility

Supports PVB, SGP, EVA, and other laminating films.

-

Why Choose a Non-Autoclave Glass Laminating Machine for Your Production Line

Discover why non-autoclave glass laminating machines are the smart choice for modern production lines. Save energy, cut costs, and get quality glass from a trusted China supplier.

넶0 2025-10-14 -

Why More Manufacturers Are Choosing Autoclave Free Laminated Glass Machines

Laminated glass is ubiquitous in all walks of life, from car windshields to building windows. Laminating two or more layers of glass and film together is how laminated glass is produced. Autoclave machines have been used for decades to accomplish this task. But now, more and more manufacturers are beginning to use autoclave-free laminated glass machines. What's the reason? Let's take a quick look.

넶18 2025-08-25 -

Maintenance Tips for Non Autoclave Laminated Glass Machine

Non autoclave laminated glass machines are the workhorses of glass production, but as with any piece of machinery, they need to be properly maintained to ensure they function properly. As compared to autoclave machinery, they apply lower pressures, so their parts wear differently. Following these simple tips can keep your equipment running smoothly, avoid breakdowns, and ensure your glass products maintain high quality.

넶21 2025-08-01 -

Energy-Saving Autoclave Free Glass Laminating Machine: Eco-Friendly Lamination Solution

The energy-saving autoclave free glass laminating machine does not require an autoclave, reduces energy consumption without affecting the quality of the lamination, and provides an environmentally friendly solution for modern glass manufacturing.

넶29 2025-07-18

NEWS INFOEMATION

-

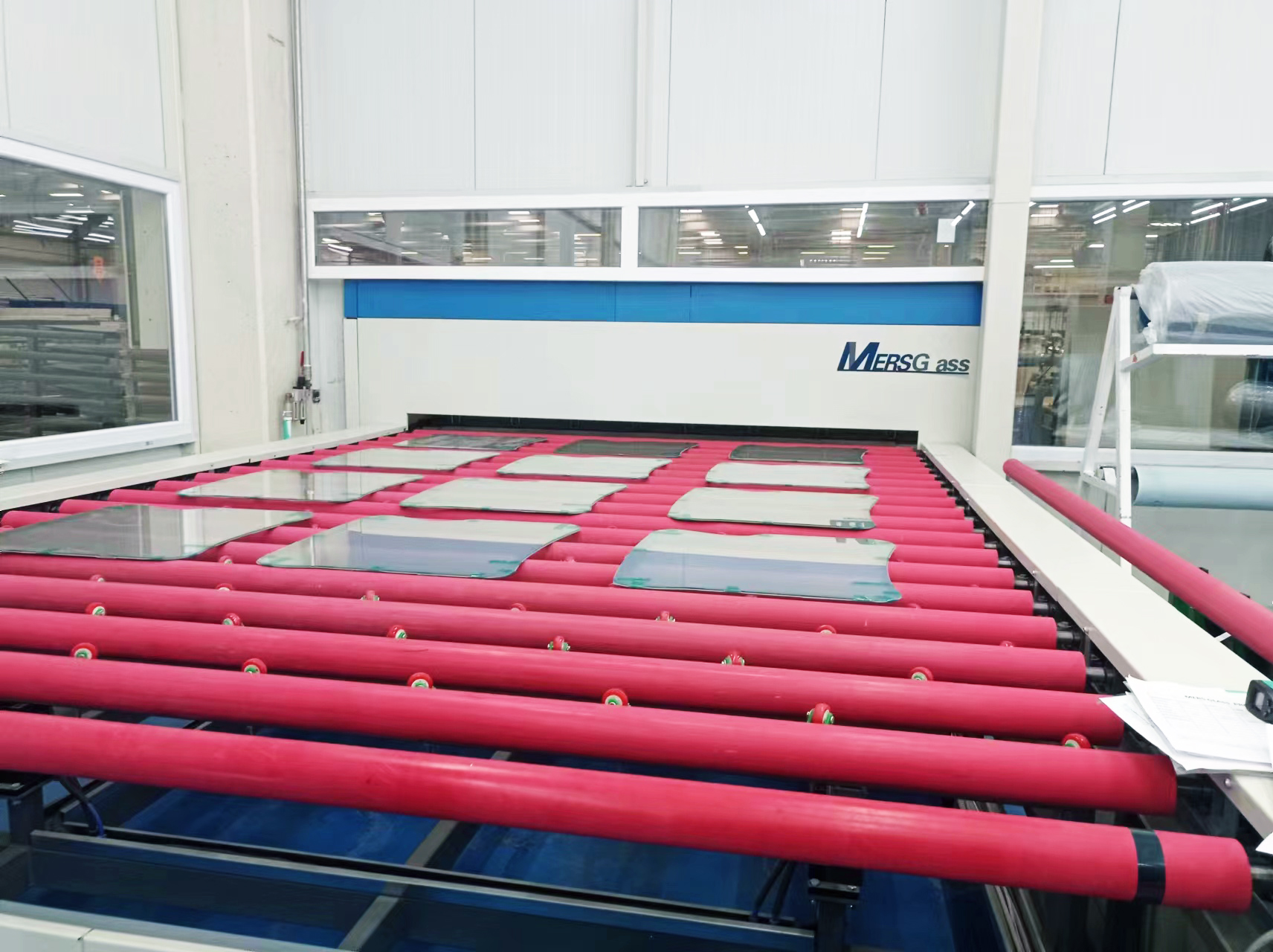

Laminating Continious Line, A revolutionary laminating solution that eliminates the need for an autoclave or humidity-controlled environment. Designed for flexibility and efficiency, this automated machine processes PVB, SGP, and EVA films with exceptional performance.

Key Highlights:

Fully automated operation with a user-friendly touch screen interface.

Versatile cycle time of 7-17 minutes, ideal for both bulk production and single-piece runs.

Customizable for various glass sizes, thicknesses, and curvatures.

Experience a seamless laminating process tailored to your production requirements.Non-Autoclave Continuous Laminating Machine for PVB/SGP/EVA

-

-

Customize your laminating system with optional components designed to optimize production, improve worker efficiency, and ensure process stability under varying conditions.

Available Components:

Semi-Automatic Assembly Machine: Reduces labor requirements and eases the handling of large glass pieces.

Cooling Machine: Essential for flat glass production, preventing cracks caused by rapid temperature changes.

Additional Machine: Ensures year-round process stability and is critical for curved glass laminating.

Tailor your setup to meet your specific production needs with these versatile and practical add-ons.Optional Components for Enhanced Laminating Efficiency

-

-

Non-Autoclave PVB/SGP/EVA Laminating Furnace

Delivering exceptional value, our heavy-duty laminating furnace is engineered for durability, efficiency, and user-friendly operation. Designed to handle both EVA, PVB, and SGP films, this machine ensures reliable performance for long-term production needs.

Key Features:

Robust Construction: Built with high-tensile steel for heavy workloads.

Versatile Production: Accommodates single or multiple pieces per batch.

Precision Control: PLC touch screen interface for easy adjustment of temperature and operational parameters.

Optimized Efficiency: Insulated cabin walls for faster heating and energy conservation.

Leak-Proof Operation: High-quality tear-resistant rubber bags with secure finger-closure seals.

Backed by a 1-year warranty, this laminating furnace offers unmatched affordability and performance for glass laminating projects. -

ABOUT US

Xi'an Mers Electric Equipment Co, Ltd. manufactures Non-Autoclave laminating machines. Our focus has been on developing new techniques that make our machines both safer to operate and greatly improve efficiency. Mers has been producing quality machines for more than 10 years.

Our continuous glass laminating machines work with standard PVB, SGP and EVA film as well as others. Each batch of glass is ready within 7-17 minutes depending on glass thickness and which film is used. Our machine can operate in bulk quantities or with single pieces. The highly automated design is easy to operate and one only needs to load glass into the uploading section. All processing would be finished by the machine itself, the finished glass would be conveyor fed to the unloading section.

PRODUCTS

Tel. : 86-1360-9152-138

Email: mersglass@gmail.com

Web: www.mersglass.com

Addr.: No. 3, Dianzi West St., Electronic Industrial Park, High-tech Zone, Xi'an

Whatsapp: