Revolutionizing Bulletproof Glass with MERS Non-Autoclave Technology

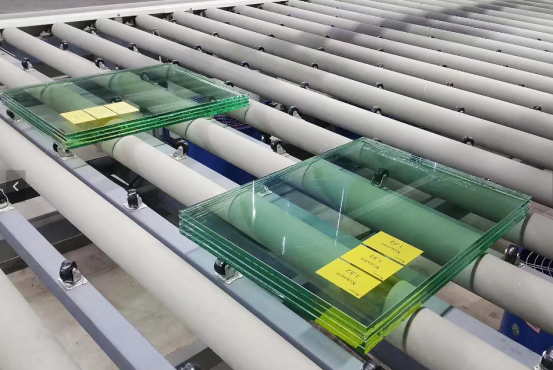

Golden Evermore Engineering Supp is a leading company in the production of bulletproof glass, specializing in using advanced technology to deliver high-quality, reliable solutions for both commercial and security applications. One of their key innovations isMERS Continuous Non-Autoclave PVB/SGP Laminating Line, which plays a critical role in the manufacturing process of bulletproof glass.

The Role of Laminating Technology in Bulletproof Glass

Bulletproof glass, also known as ballistic glass, is a type of strong, optically transparent material that is highly resistant to penetration by bullets. The glass typically consists of multiple layers of glass and polyvinyl butyral (PVB) or SentryGlas (SGP) interlayers. The laminating process binds these materials together to create a structure capable of absorbing and dispersing the energy from an impact, making it impenetrable by standard firearms.

Golden Evermore Engineering Supp's use ofMERS Continuous Non-Autoclave Laminating Linerevolutionizes traditional bulletproof glass production methods. Traditional processes often involve the use of autoclaves, which are high-pressure chambers that apply both heat and pressure to bond the layers. This method, while effective, can be time-consuming and energy-intensive, limiting production efficiency.

Advantages of MERS Continuous Non-Autoclave Technology

MERS Continuous Non-Autoclave Laminating Lineeliminates the need for autoclaves, significantly improving both the speed and cost-effectiveness of the laminating process. Instead of relying on pressure and heat, this technology uses a continuous process where layers of glass and interlayer materials, such as PVB or SGP, are bonded together through a more efficient, lower-energy method. This offers several advantages:

- Increased Production Efficiency: Without the need for autoclave processing, Golden Evermore can produce bulletproof glass at a faster rate, significantly reducing production time and increasing output.

- Energy Savings: Autoclave systems consume a significant amount of energy. By using a non-autoclave system, the MERS technology reduces energy consumption, making the production process more environmentally friendly and cost-effective.

- Enhanced Product Quality: The continuous laminating process ensures a uniform and consistent bonding of layers, resulting in bulletproof glass that meets or exceeds safety standards. The non-autoclave system also reduces the risk of defects caused by uneven pressure or heat distribution.

- Versatility in Production: The MERS laminating line can be adapted for various types of glass, including curved or flat panels, and can accommodate different thicknesses and interlayer materials depending on the level of ballistic protection required.

Applications of Bulletproof Glass

The bulletproof glass produced by Golden Evermore Engineering Supp serves a wide range of industries and applications. It is commonly used in security-focused settings, such as banks, government buildings, armored vehicles, and military installations. The company also caters to the commercial market, providing custom solutions for high-end retail spaces, luxury hotels, and corporate offices where enhanced security is essential.

In conclusion, Golden Evermore Engineering Supp's integration ofMERS Continuous Non-Autoclave PVB/SGP Laminating Lineinto their production process sets them apart as a leader in the bulletproof glass industry. By prioritizing innovation, efficiency, and product quality, the company is able to deliver superior ballistic protection solutions to meet the evolving demands of both commercial and security sectors.

-

Why Choose a Non-Autoclave Glass Laminating Machine for Your Production Line

Discover why non-autoclave glass laminating machines are the smart choice for modern production lines. Save energy, cut costs, and get quality glass from a trusted China supplier.2025-10-14

-

Why More Manufacturers Are Choosing Autoclave Free Laminated Glass Machines

Laminated glass is ubiquitous in all walks of life, from car windshields to building windows. Laminating two or more layers of glass and film together is how laminated glass is produced. Autoclave machines have been used for decades to accomplish this task. But now, more and more manufacturers are beginning to use autoclave-free laminated glass machines. What's the reason? Let's take a quick look.2025-08-25

-

Maintenance Tips for Non Autoclave Laminated Glass Machine

Non autoclave laminated glass machines are the workhorses of glass production, but as with any piece of machinery, they need to be properly maintained to ensure they function properly. As compared to autoclave machinery, they apply lower pressures, so their parts wear differently. Following these simple tips can keep your equipment running smoothly, avoid breakdowns, and ensure your glass products maintain high quality.2025-08-01

-

Energy-Saving Autoclave Free Glass Laminating Machine: Eco-Friendly Lamination Solution

The energy-saving autoclave free glass laminating machine does not require an autoclave, reduces energy consumption without affecting the quality of the lamination, and provides an environmentally friendly solution for modern glass manufacturing.2025-07-18